Diversified Industrial

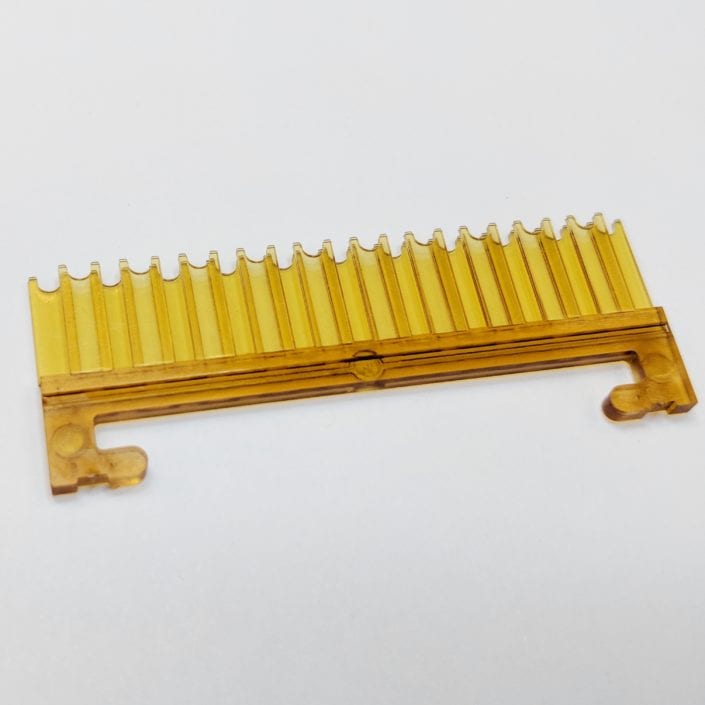

From precision molded high temperature thermoplastic seals to gears, we incorporate unique materials and processes to create high-volume, custom-engineered solutions. We are particularly adept at creating components which need to excel in high temperature or aggressive chemical environments or where lubricity, wear, and dielectric properties are important.